Shaping the Ships in Samho

Photos by Kelsey Rivers

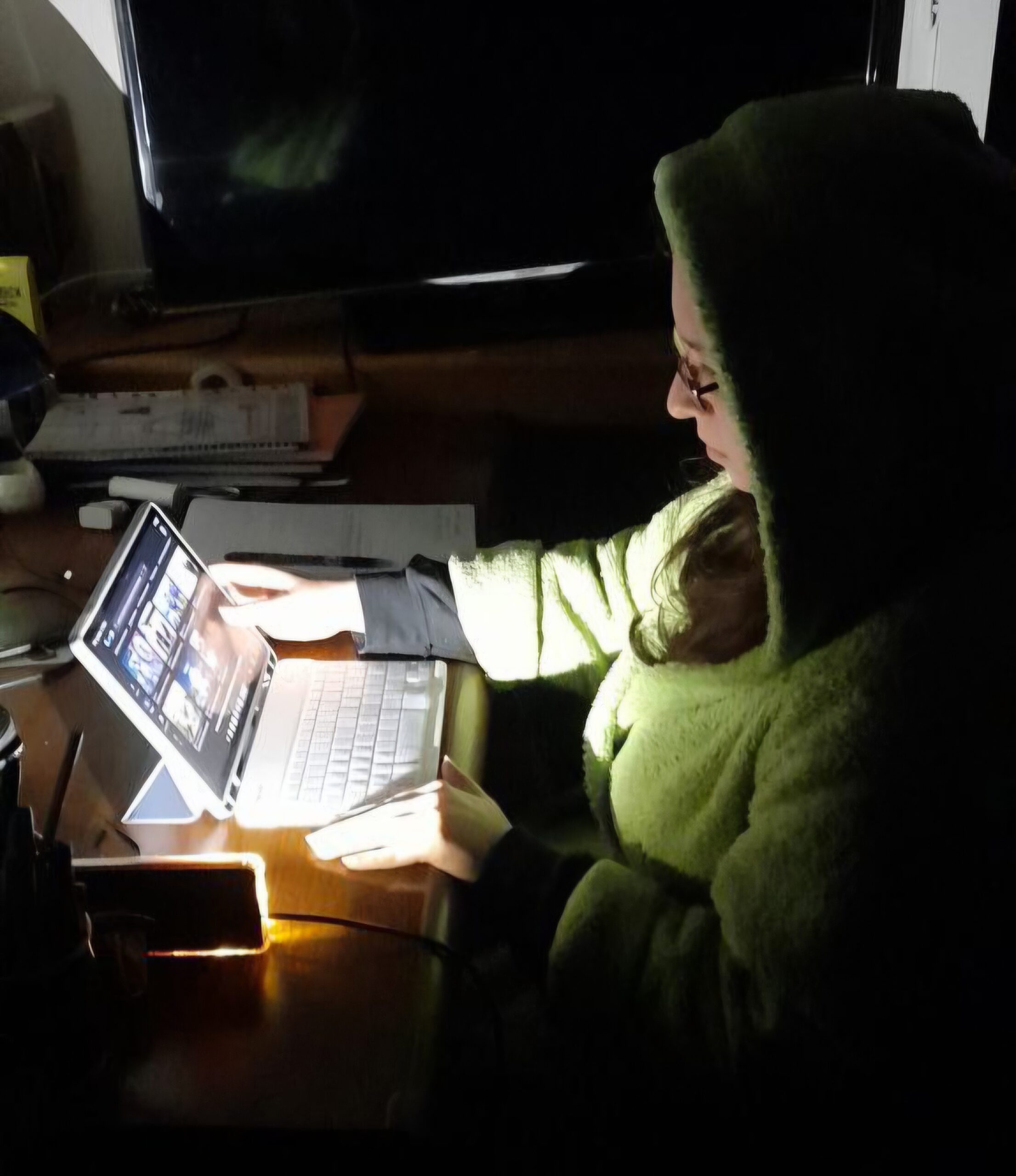

I zipped along the deserted streets of Samho, perched on the back of Sam’s dusty moped, the wind whipping my hair into my eyes and the purr of the engine drowning out our voices. We were on our way to his company, so I could learn a little bit more about this place opposite Mokpo, the mirrored city across the river.

When you travel to the end of the Yeongsan River, where it opens up into the sea, you will find yourself in Mokpo. This port city has a seedy reputation (I’ve heard murmurs that it was the inspiration for a gangster movie), but really this is an up-and-coming city, the provincial capital of Jeollanam-do, with new high-rise apartments going up in the expensive Namak suburb all the time. But from the trendy, second-floor windows of the coffee shops along the shore, you can see an altogether different city, just across the dam. This is Samho, the heart of Mokpo’s economic development, the location of one of Korea’s largest shipyards.

Now, I’ve met countless Koreans around Mokpo who work in some capacity for the shipyards as engineers, safety inspectors, etc. I’ve also met a fair share of foreign workers, from Greece, France, Italy, Finland… Almost all living in the same fancy neighborhood of Namak. However, there is a whole subset of workers whom I rarely come into contact with, but their presence becomes readily apparent when you walk around the streets of Samho. Every other shop is an Asian or halal mart, hawking so much coveted cilantro that it puts the sprigs available at Emart to shame. Uzbekistani restaurants stand next to Filipino bars, and Chinese-style lamb BBQs are seemingly the most popular eateries around. This is a whole other world from Mokpo, one that doesn’t feel quite so Korean. This is where Samir Chhetri, one of my closest friends in Korea, lives and works.

Samir (Sam) came from Nepal about four years ago, hired on a five-year contract to work for the shipbuilding industry. Before coming to Korea, he was working on a University degree in business, but when he heard about this opportunity to come earn money in Korea (one month’s salary, enough to live on for a year!) he took the necessary tests and studied a little Korean to qualify, and then he was on his way. “I knew that it would be a job in an industrial place,” he said, when I asked if he knew what he was getting into. He worked his first job at a company called Jeyngsu Engineering, for about three years. He liked it there – his job was to assist engineers in making calculations, his salary was good, and the work environment was friendly.

However, working for the shipbuilding industry is a tenuous business these days. Last year, the industry went through a rough period, with many companies going bankrupt due to a combination of trade stagnation, low shipping rates globally, and an oversupply of ships on the market. According to Sam, the industry suffered a six-billion-dollar loss. With no way out of their staggering debt, companies were forced to restructure or declare bankruptcy, resulting in massive layoffs. Sam was one of the unfortunates, losing his job with Jeyngsu and forced to bounce around to three different companies, joining each one briefly before it too went under. He remembers the false hope of being offered a position, but with the company’s reluctance to give him a contract, he kept having to wait for something more solid (and legal) to come his way.

When we arrived at Sam’s company, we snuck over the metal gate blocking the entrance and made our way towards a large building across the yard. The yard was strewn with metal parts in all shapes and sizes, the pieces to some ship-shaped puzzle that I couldn’t begin to imagine. The warehouses at the back had a narrow passage between them that Sam ducked into, moving to an electrical box to turn on lights deeper in. As we made our way to the entrance of the warehouse, the high walls of the buildings blocked out the sun, creating such deep shadows on either side of me that I couldn’t tell if there were walls there or not, so eerily dark that it felt like I was walking next to an abyss, making my hair stand on end.

When we maneuvered through exposed piping and hanging wires to a small door on the side of the building, I stepped into a huge, cavernous room, with all the walls painted black and made of some flexible, tarp-like material. Spaced at regular intervals around the room were large pipes and ducts, rusting and dull now, waiting to be blasted in preparation for painting. Sam stooped and pinched up some of the sand and black dust gathered in drifts all over the floor. He explained that this was iron dust, a mix of what was used to clean the metal, as well as what was actually blasted off. The dust gets everywhere and surely isn’t good for your health, if the signs posted outside exhorting you to wear a suit and mask are to be believed. My eyes, throat, and nose were already starting to itch and water (and would do so for the rest of the day.) Sam said that sometimes when the dust got into your eyes, you had to use a magnet to get it out – demonstrating the proper technique to magnetically attract iron dust out of one’s eye.

Later, over a cup of coffee at a café in Mokpo, Sam seems tired. He gestures to his face, where once his skin was smooth, but now is breaking out. He explained that he is a “blaster,” he uses a high-powered hose to sandblast the grit and surface off of the metal parts that go into making a ship, preparing them for painting. The pressure and force of the sand blasted from the hose is so powerful that if you get hit, it could kill you. It’s terribly loud, so they have to wear ear plugs, a full body suit, and a helmet – he says it reminds him of an astronaut’s suit. The air is so dusty and cloudy; you can’t see too far in front of you. And even though Sam dons a full body suit and air-tight helmet, the dust still manages to get in, getting everything dirty. Attached to the helmet is a tube that pumps fresh oxygen into the suit while you’re working. If the hose gets disconnected or stops working, you have to hurry outside of the warehouse and remove the helmet as it will get steadily harder and harder to breathe – you could asphyxiate before long. The job is tough and seems as though it would be a likely candidate for Mike Rowe’s Dirty Jobs.

The work isn’t painful, but it is definitely physically demanding. I tried to lift the hose that Sam uses to blast, and even without the powerful force of the sand being blasted out, it was heavy. He said that if you weren’t careful, you could get knocked off your feet by the force. “It’s hard, but I like it here” he said.

When we left the building and were headed back to the moped, a barking dog made us look towards the company dormitory on the other side of the yard, where some young men watched us with interest. Sam of course knew them, and so we were invited into the communal kitchen to share a late lunch of curry, rice, and fried fish (caught by the Nepali workers themselves from the Yeongsan River). The men made room for us at the table, and two quiet women smiled cautiously. Sam was friends with one of the guys, a football player; Sam moonlights as a photographer for the Nepali football team, one of the many community organizations that keep the foreign workers feeling less isolated while they are so far away from home.

The Nepali community is indeed quite large, with its own community organizations to match. Sam jokingly called the Nepali group the “Mokpo chautari” which means something like “gathering place” in Nepali, but has connotations of criminal activity. This organization puts together picnics, festival celebrations, and trips to different parts of Korea. And when members are going through difficult times financially (or otherwise), the group raises funds to help those in need. Sam said that it was not difficult for him to meet friends from Nepal, that the Nepali group is very tight-knit and helps create a home-away-from-home feel. Sam refers to each of his friends as his “brother,” and with this self-created family, households are fluid and characterized by camaraderie. One’s door is always open in the Nepali community.

Back on the moped, we zoom down the streets of the industrial area, eerie six-lane roads devoid of all movement and life, except for the occasional moped like ours, the ubiquitous form of transportation for the foreign workers of Samho. The huge scale of the roads and warehouses meant to accommodate the movement of half-completed oil tankers and barges emphasized how deserted the shipyards are on the weekend. Sam said it livens up during the week, but still I wonder how lively it can be with the industry slogging through a slump. Although his current job is exhausting and dangerous, the company is also stable, so he feels that he can stay with them for at least the rest of the year, no matter what shape the shipbuilding industry is in by 2018.

And after Sam has completed his five-year contract? There are many roads open to him, including renewing for another five years. However, Sam feels the need to move on. He said that bringing in foreign workers like this is “good for the Koreans and good for us, too. But, it’s a waste of time and energy from what I really want to be. I can make money here, but it is not what I want to do.”

Sam has a lot of dreams, dreams that every day he is working towards. Korea, although valuable in exposing him to other cultures and people, is simply a pit stop. He is positive that the future holds bigger and better things for him.